There are a lot of at-home masks circulating the Internet and a lot of hospitals, doctors, and physicians trying to get their hands on them. For the last week, I’ve been designing, stitching, prototyping, 3D printing, and diving in and I’m going to share with you what I’ve learned.

First a warning: No home-made part or mask can curreently claim any certification and shouldn’t be compared or substitute for any official FDA tested product. Fabric masks and 3D-printed parts are prone to quality issues, poor seals and non-functioning filters. These designs should be used as a last resort and even then should be used with caution. Using any personal protection equiptment (PPE) without proper qualifiction and testing is dangerous and can give you a false sense of security.

That being said, we’re going to dive into three things people are making right now.

The first is sewn or stitched face masks. Such masks are generally not “air-tight” like a standard N95 mask but these masks are being used by doctors, nurses and staff for extending the life of a standard mask. They are also being used for patients and other staff that would traditionally not be given any mask to help protect them.

All it requires is a cotton fabric or a t-shirt, scissors and ideally a sewing machine. There are many instructions and examples that go into detail on how to do this. Here are many popular designs: Design 1, Design 2. Design 3. Design 4, Design 5, Design 6. There are many options in the designs but they are easy to produce and people are producing tends of thousands of these.

According to this article based on this research, cotton t-shirt fabric as the most suitable material however different instructions offer alternatives such as unwoven polypropylene, pillow-cases, microfiber, and dish-towels. What I’m hearing is that hospitals aren’t being picky but they are creating in-take procedures to accept sewn masks, sterilize them and clean them. At the very least, you can make yourself a mask for when you go out shopping.

There is a lot of experimentation for using an air-duct filter material, usually rated with a MERV rating of 12-15 but I haven’t found articles on the effectiveness of such a filter for personal use. Since these types of masks aren’t air-tight it’s unclear if this type of filter provides additional protection. If you’re using a filter material other than cotton, consider making it removable.

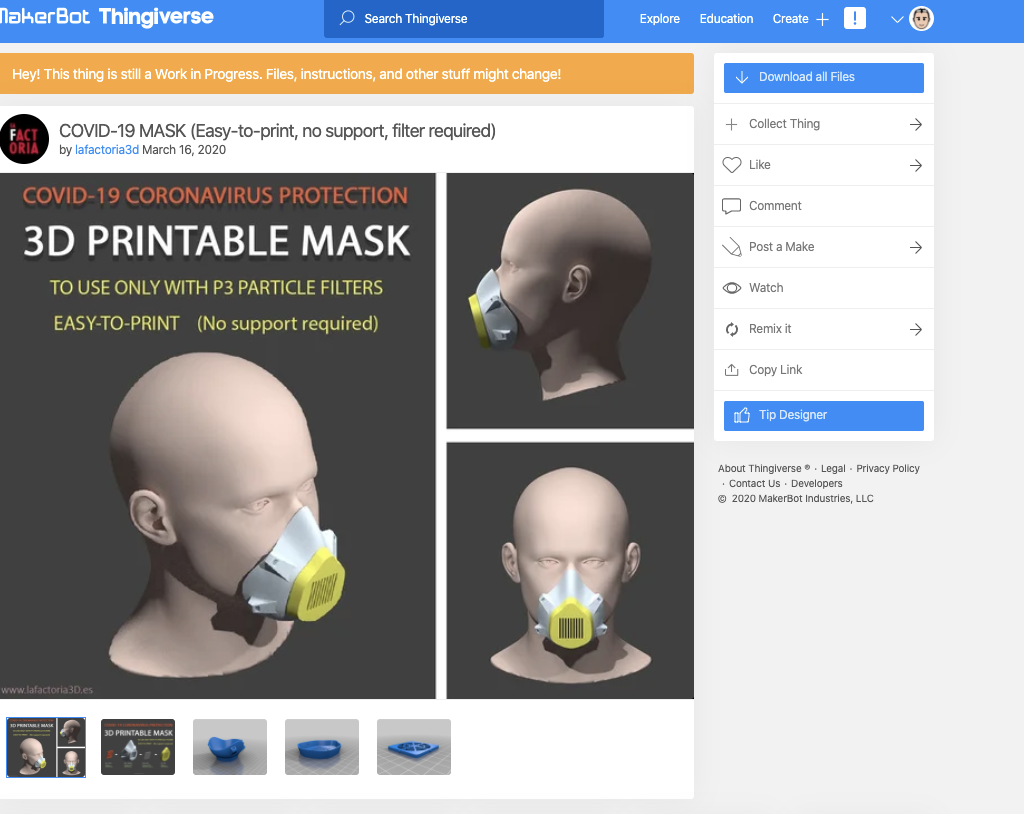

The second area of PPE innovation is around the area of 3D printing. This breaks into two areas, the first is what I’ll call ready for production and the other area is R&D. Since this entire space is only a few weeks old things are moving very quickly and I hope more things will get past R&D and move into production. (This could talk about how to make a prototype)

On the production side of things, 3D printed face-shields are the easiest to produce.

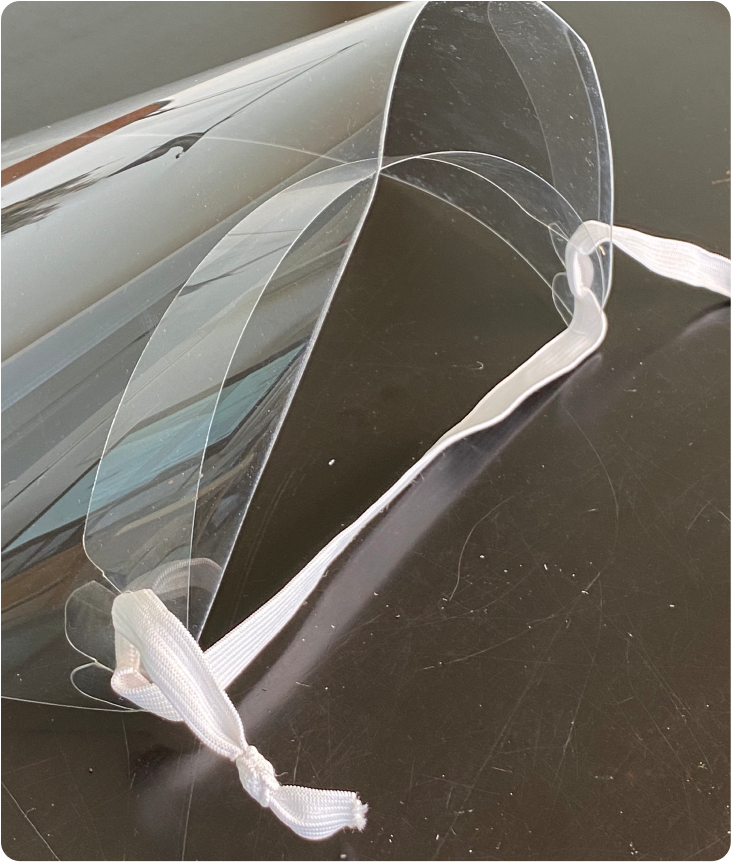

Face-shields protect the face, eyes, and mouth from large droplets such as sneezes and coughs. There are a number of great designs and they require just a 3D printer and some acrylic sheets. I’ve even included a design that can be made with just clear plastic and an elastic band. Here are many popular designs: Design 1, Design 2, Design 3, Design 4, Design 5 There’s a great video that goes into more detail on this. There are also face-shield designs made without a 3D printer using just foam and scissors and another from Bauer

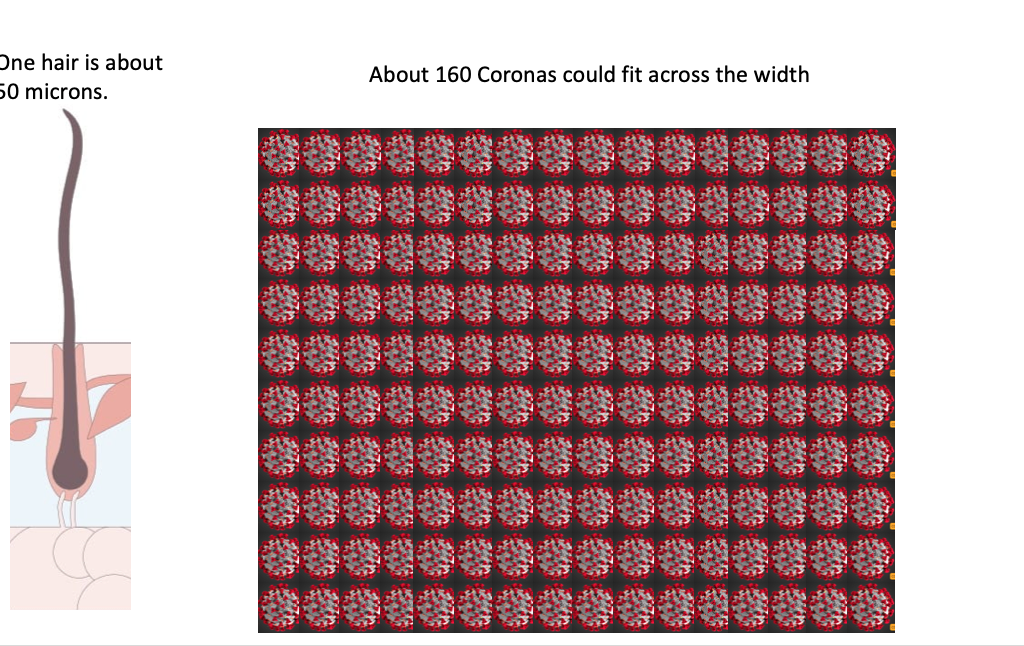

In the realm of 3D-printed R&D projects, there are a number of explorations into applications of the technology to print more complex parts that are needed. I call these R&D because as far as I know they are still being validated. Validation and testing of devices is critical because of how small the Covid virus is…

While sewn masks that are designed to block large droplets is one thing, trying to block something that’s that small requires a lot of testing and validation.

The idea of 3D printed masks sounds awesome and there are a ton of designs floating around the Internet but going from something that prints, to something that can actually seal and works for an eight-hour shift is really hard. There are thousands of people working on this problem and I hope we’ll get to a design that will work but for the time being, we are talking about prototypes.

There are three major problems that are being worked on.

- Getting a reliable seal to your face for a wide variety of face sizes.

- Getting a reliable filter and seal between the filter and the mask.

- Ensuring that the filter media is any good and prevents air from flowing around the filter.

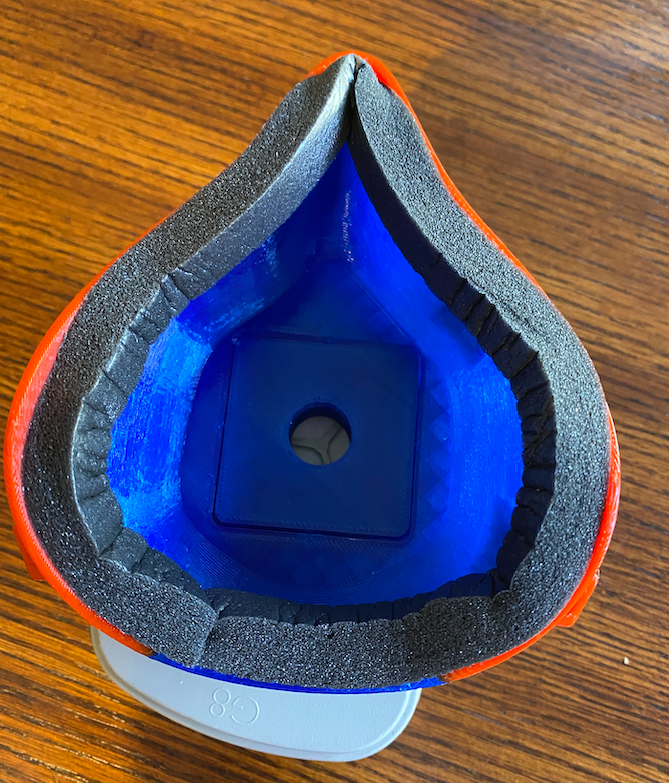

The first problem is that all faces are different. People’s heads come in all shapes and sizes and unfortunately, the most common 3D printing material is PLA plastic. This is a fairly common plastic but it’s also hard, so unlike silicone or rubber, it won’t bend much to the variety of faces.

Traditional masks and respirators often have bendable portions that fit snug around the nose and are made from a material that can conform to the face. People are trying to design around this issue with a wide variety of ideas:

- Producing a wide variety of sizes

- Trying to mold the plastic using a heat gun or microwave

- Using a softer plastic for example PTU

- Use of rubber foam to line the inside of the mask

- Using an over-printed inner gasket or gluing parts of a silicone to the inner surface.

Each of these solutions is being worked on and I’m hopeful that one or several will pass clinical tests and validation.

The second problem is the filter. Some designs are using commercial filters that are available and click-in or screw into a design. Other teams are modifying anesthesiology filters to work with masks or attaching various HEPA filters and hand-made MERV/Cotton filter combinations.

The challenge with all these designs is that they need to be safe. Mass General Covid Innovation Group is passing designs through a number of validations:

- Fit testing

- Exhalation resistance

- Inhalation Resistance

- Filter Efficiency

- Bacterial Filteration

- Ability to scale production to thousands quickly

- Failure mode effects analysis (FMEA)

In addition, designs are being evaluated for how the device can be sterilized and used/re-used for long durations of time. Such a design and product challenge would be aggressive for teams to produce in a six-month window. I’ve been watching teams bring solutions and prototypes together in the last two weeks working day and night.

In addition to respirator style-masks, there are efforts to print parts for ventilators, over the head -PARP-style respirators, and more. Teams from individual maker spaces and large companies are participating. Companies like New Balance and Gap are turning their sneaker, and clothing making machinery and skills into making fabric filters. Companies like Ford, GM, and Tesla are exploring how to rapidly-produce ventilators.

The R&D space is moving quickly and I’m hopeful that some of these solutions can quickly and safely helping frontline workers.

So if you have a sewing machine or 3D printer, please put to immediate use, you can start making masks and face shields today. If you still want to help but don’t know how to sew or have a 3D printer. You can help too… Stay Home!